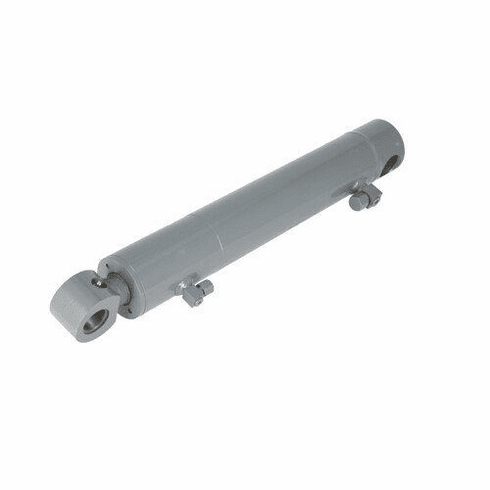

Product Description

Company Profile

MKS is a comprehensive enterprise with deep strength and rich experience in the field of hydraulic pumps, hydraulic spare parts, bearings and casting, CHINAMFG currently has 1500 emploveesmore than 400 sets of imported production equipment, heat treatment equipment, casting productionline, since its inception, we have always been commited to providing high-quality, high-performance products and services to meet the scalating needs of global customers.

The main sales of Rexroth, Eaton, Parker, Carter and other series of hydraulic pumps.At the same time, CHINAMFG can independently develop, design and customize various types of hydraulic pumps.and can produce various types of hydraulic pumps to meet the needs of different industrial fields. Hydraulic pump accessories, we provide a full range of accessories, including hydraulic cylinders,accumulators, seals, bearings, gears, etc.to ensure that customers can get timely and professional support when maintaining and replacing equipment. Bearings are an important part of our product line, and we use advanced forging technology andmaterials to produce high-precision, high-reliability bearing products. in the field of casting, we rely on richexperience and professional technical team to provide customers with customized casting services.

We always adhere to the business philosophy of customer-centric, market-oriented, and quality-oriented.By continuously optimizing the production process, improving product quality, and strengthening after-sales service, we have won the trust and praise of our customers. in the future we will continue to uphold this concept, continue to innovate and develop, and provide better products and servicesto customers around the world.

Company Environment

Other Products

Our Advantages

FAQ

Q1: How about the quality of the managements?

A: We have a complete quality control system , all of our products will be fully pre-inspection by QC departments before shipping to you.

Q2: Can you offer OEM or design services?

A: Yes, we have our own design department and production tools. We can make OEM products according to your requirements.

Q3: What are your terms of payment and delivery time?

A: We could accept T/T, Paypal, Western Union, Credit Assurance. Generally, we will arrange the shipment within 7 days after received payment.

Q4: How about warranty?

A: 12 months warranty.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.

If you have any questions or want to know more details about the product, please contact us!

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can tilt cylinders be used in manufacturing machinery for material processing?

Yes, tilt cylinders can be used in manufacturing machinery for material processing. These cylinders offer several advantages that enhance the efficiency, versatility, and precision of material processing operations. Here's a detailed explanation:

- Tilt Angle Adjustment: Tilt cylinders allow for precise tilt angle adjustment of equipment attachments, such as cutting tools, milling heads, or processing platforms. This adjustability enables operators to achieve the desired tilt angle for material processing tasks. By controlling the tilt angle, operators can optimize the cutting or processing angle, resulting in improved accuracy, quality, and efficiency.

- Material Positioning: Tilt cylinders assist in proper material positioning during processing. By adjusting the tilt angle of the equipment, operators can align the material in the ideal position for cutting, shaping, or other processing operations. This ensures consistent material engagement with the cutting tools or processing surfaces, minimizing errors and improving overall precision.

- Enhanced Accessibility: Tilt cylinders provide enhanced accessibility to the material being processed. By tilting the equipment, operators can gain better access to different areas of the material, even hard-to-reach or complex surfaces. This accessibility facilitates efficient processing and allows for the execution of intricate operations with greater ease.

- Process Optimization: Tilt cylinders contribute to process optimization by enabling operators to adjust the tilt angle based on specific material characteristics or processing requirements. For instance, certain materials may require a specific tilt angle to achieve optimal chip removal during cutting or to enhance the efficiency of material shaping. The ability to optimize the tilt angle enhances process control and ensures the desired output quality.

- Flexibility in Material Handling: Tilt cylinders provide flexibility in material handling during processing operations. They allow for the tilting of workpieces or platforms, enabling operators to orient the material in the most suitable position for processing. This flexibility accommodates various material shapes, sizes, and orientations, expanding the range of materials that can be effectively processed using the machinery.

- Integration with Automation: Tilt cylinders can be integrated with automation systems in manufacturing machinery. This integration enables automated tilt angle adjustments based on predefined parameters or sensor feedback. By incorporating tilt cylinders into automated material processing systems, manufacturers can achieve consistent and repeatable processing results, reduce manual intervention, and improve overall productivity.

Therefore, tilt cylinders can be effectively utilized in manufacturing machinery for material processing. Whether it involves tilt angle adjustment, material positioning, enhanced accessibility, process optimization, flexibility in material handling, or integration with automation, tilt cylinders contribute to improving the efficiency, precision, and versatility of material processing operations in the manufacturing industry.

Can tilt cylinders be used in material handling equipment for load manipulation?

Yes, tilt cylinders are commonly used in material handling equipment for load manipulation. These cylinders play a crucial role in enhancing the versatility and efficiency of equipment designed for lifting, moving, and manipulating various types of loads. Here's a detailed explanation:

- Load Tilting: Tilt cylinders enable material handling equipment to tilt loads, allowing for precise positioning and manipulation. By adjusting the tilt angle, operators can optimize load distribution, accommodate uneven surfaces, and ensure secure handling. Tilt cylinders provide the necessary force and control to achieve the desired load tilting, enhancing safety and operational efficiency.

- Load Stabilization: In material handling applications, load stability is essential to prevent shifting, sliding, or toppling during transport or manipulation. Tilt cylinders contribute to load stabilization by allowing operators to adjust the load tilt angle and maintain a stable position. This feature is particularly important when dealing with unbalanced or irregularly shaped loads. By utilizing tilt cylinders, material handling equipment can ensure safe and secure load manipulation.

- Load Dumping: Tilt cylinders also facilitate load dumping in certain material handling equipment. For example, in dump trucks or dumpers, tilt cylinders allow the controlled tilting of the cargo bed to unload the materials. By actuating the cylinders, operators can achieve controlled and efficient dumping of the load, minimizing material waste and optimizing productivity.

- Load Rotation: Some material handling equipment, such as rotating telehandlers or rotating fork attachments, utilize tilt cylinders to enable load rotation. By adjusting the tilt angle, the equipment can rotate the load horizontally, providing flexibility in positioning or transferring materials. Tilt cylinders provide the necessary force and control for smooth load rotation, expanding the equipment's capabilities.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with hydraulic systems present in material handling equipment. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for load manipulation. The hydraulic system allows for precise and responsive movement, enabling operators to adjust the load tilt angle according to specific requirements.

- Customization and Compatibility: Tilt cylinders can be customized to suit different types of material handling equipment and load manipulation applications. Manufacturers offer tilt cylinders with varying specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of material handling machinery.

Therefore, tilt cylinders are widely used in material handling equipment for load manipulation tasks. Whether it involves load tilting, stabilization, dumping, or rotation, tilt cylinders provide the necessary force, control, and flexibility to handle various loads efficiently and safely. Their integration with hydraulic systems and customization options make them indispensable components in material handling applications.

How does a tilt cylinder contribute to precise equipment tilt control?

A tilt cylinder plays a crucial role in achieving precise equipment tilt control. It provides the necessary force and control mechanisms to enable controlled and accurate tilting movements. Here's a detailed explanation of how a tilt cylinder contributes to precise equipment tilt control:

- Force Generation: A tilt cylinder is a hydraulic component that generates the force required to tilt or angle the equipment. It consists of a cylinder housing, piston, and rod assembly. When hydraulic pressure is applied to the cylinder, the piston moves, exerting force on the attached component. The force generated by the tilt cylinder allows for precise and controlled tilting of the equipment.

- Controlled Fluid Flow: Tilt cylinders utilize hydraulic fluid to transmit force and control the tilting movement. The flow of hydraulic fluid is regulated by control valves, which allow operators to control the speed, extent, and direction of the tilt. By adjusting the control valves, operators can achieve precise control over the fluid flow, enabling accurate and controlled tilting of the equipment.

- Range of Motion: Tilt cylinders provide a specific range of motion, allowing for controlled tilting within that range. The range of motion is determined by the design and construction of the cylinder, as well as the attachment points on the equipment. The defined range enables operators to tilt the equipment to the desired angle with precision, ensuring precise control over the tilt position.

- Feedback Mechanisms: Some tilt cylinders incorporate feedback mechanisms such as limit switches or sensors. These mechanisms provide real-time feedback on the position and angle of the tilted component. By monitoring the feedback, operators can precisely adjust the tilt cylinder to achieve the desired tilt angle. This feedback loop enhances the precision of equipment tilt control.

- Operator Input: Tilt cylinders are typically operated by equipment operators who have control over the hydraulic system. Operators can manipulate the control levers or buttons to adjust the hydraulic pressure and flow, thereby controlling the tilt cylinder's movement. The operator's skill and experience in operating the tilt cylinder contribute to achieving precise equipment tilt control.

By combining the force generation capabilities, controlled fluid flow, defined range of motion, feedback mechanisms, and operator input, a tilt cylinder enables precise control over the equipment's tilt. This precision is essential for applications where accurate tilting is required, such as in construction, mining, agriculture, and material handling. The ability to achieve precise equipment tilt control enhances operational efficiency, productivity, and safety in various industries.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China wholesaler Suitable for Cat Bulldozers D10t D10r D10n 9t2869 Bucket Lift 2320652 Bucket Tilt 1926445 Ripper Lift 4t9977 Ripper Tilt Hydraulic Cylinder with Best Sales "><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China wholesaler Suitable for Cat Bulldozers D10t D10r D10n 9t2869 Bucket Lift 2320652 Bucket Tilt 1926445 Ripper Lift 4t9977 Ripper Tilt Hydraulic Cylinder with Best Sales ">

editor by Dream 2024-10-08