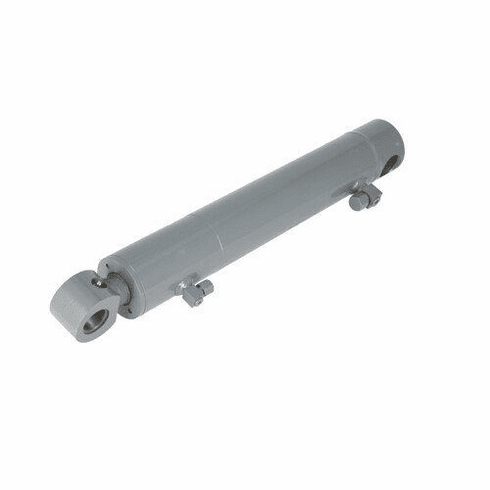

Product Description

| Product name | Cabin Tilt Cylinder |

| Part number | 50571651 55713057 |

| Size(mm) | Standard size |

| MOQ | 10PCS |

| Delivery time | Within 15 days |

| Port | HangZhou |

| Quality | OEM quality |

| Quality guarantee | 6 months |

| Packing | Customized packing |

Related product we can supply:

| S.N | Product name | Part number | MOQ | Application |

| 1 | Cab Tilting Cylinder | -01 -01 | 10 PCS | Truck brake parts for European truck |

| 2 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 3 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 4 | Cab Tilting Cylinder | 45104-5 | 10 PCS | Truck brake parts for European truck |

| 6 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 7 | Cab Tilting Cylinder | 458662.240 458662-240 | 10 PCS | Truck brake parts for European truck |

| 8 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 9 | Cab Tilting Cylinder | 182.505711 458662.250 | 10 PCS | Truck brake parts for European truck |

| 10 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 11 | Cab Tilting Cylinder | 182.505711 453198.237 | 10 PCS | Truck brake parts for European truck |

| 12 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 13 | Cab Tilting Cylinder | 50571651 | 10 PCS | Truck brake parts for European truck |

| 14 | Cab Tilting Cylinder | 10 PCS | Truck brake parts for European truck | |

| 15 | Cab Tilting Cylinder | 83417236099 | 10 PCS | Truck brake parts for European truck |

| 16 | Cab Tilting Cylinder | 73 99458298 99458304 | 10 PCS | Truck brake parts for European truck |

| 17 | Cab Tilting Cylinder | 5 415711 | 10 PCS | Truck brake parts for European truck |

| 18 | Cab Tilting Cylinder | 41281222 55713053 | 10 PCS | Truck brake parts for European truck |

| 19 | Cab Tilting Cylinder | 99458304 41241683 | 10 PCS | Truck brake parts for European truck |

| 20 | Cab Tilting Cylinder | 504065532 3943332 8151731 | 10 PCS | Truck brake parts for European truck |

| 21 | Cab Tilting Cylinder | 748257194 | 10 PCS | Truck brake parts for European truck |

| 22 | Cab Tilting Cylinder | 81417239059 | 10 PCS | Truck brake parts for European truck |

| 23 | Cab Tilting Cylinder | 157196 157196 1095 | 10 PCS | Truck brake parts for European truck |

| 25 | Cab Tilting Cylinder | 1794907 1855566 22571 | 10 PCS | Truck brake parts for European truck |

| 26 | Cab Tilting Cylinder | 98455864 8138252 | 10 PCS | Truck brake parts for European truck |

| 27 | Cab Tilting Cylinder | 1549740 1397310 15751656 | 10 PCS | Truck brake parts for European truck |

| 28 | Cab Tilting Cylinder | 1378531 361453 3883524 575152 575154 | 10 PCS | Truck brake parts for European truck |

| 29 | Cab Tilting Cylinder | 375351 575172 | 10 PCS | Truck brake parts for European truck |

| 30 | Cab Tilting Cylinder | 1534976 1397310 1575165 1804064 1234778 1725376 25379038 8257196 | 10 PCS | Truck brake parts for European truck |

| 31 | Cab Tilting Cylinder | 1720925 1512253 | 10 PCS | Truck brake parts for European truck |

| 32 | Cab Tilting Cylinder | 125715 1295729 1345473 | 10 PCS | Truck brake parts for European truck |

| 33 | Cab Tilting Cylinder | 748257196 | 10 PCS | Truck brake parts for European truck |

| 34 | Cab Tilting Cylinder | 5 | 10 PCS | Truck brake parts for European truck |

| 35 | Cab Tilting Cylinder | 5 | 10 PCS | Truck brake parts for European truck |

Q1. What's your term of delivery?

A: A. EXW, FOB, CFR, CIF, DAP, DDP. If you have warehouse or agent in China, we will be glad to send the goods to as your required.

Q2.What's your term of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. Can you produce according to the samples?

A:Yes, we can produce by your samples or technical drawings. OEM services are available.

Q4. How about your delivery time?

A: For stock orders, will arrange the shipment within 3-5 days. For bulk order, it will take 20 days after receiving your advance payment.

Q5. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

wa 13317141798 Floria

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 6 Months |

|---|---|

| Type: | Brake System |

| Certification: | ISO/TS16949, ISO13485, IATF-16949, ISO9001, ISO9002 |

| Main Market: | South America, Eastern Europe, Mild East, Southeast Asia, Africa, Eastern Asia, Oceania |

| Product Name: | Cabin Tilt Cylinder |

| MOQ: | 10PCS |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

Can tilt cylinders be used in agricultural machinery for field work?

Yes, tilt cylinders can be used in agricultural machinery for field work. These cylinders play a valuable role in enhancing the functionality and productivity of agricultural equipment used for various tasks in the field. Here's a detailed explanation:

- Implement Control: Tilt cylinders enable precise control of agricultural implements, such as blades, plows, cultivators, and harrows. By adjusting the tilt angle, operators can optimize the implement's position and orientation for efficient soil preparation, leveling, seedbed creation, and other field work activities. Tilt cylinders provide the necessary force and control to achieve the desired implement tilt, enhancing operational efficiency and effectiveness.

- Contour Following: Tilt cylinders allow agricultural machinery to follow the contours of the field surface. By adjusting the tilt angle of the implement, the equipment can adapt to uneven terrain, ensuring consistent depth and contact with the ground. This contour following capability enhances seed placement accuracy, promotes uniform soil tillage, and reduces the risk of damaging crops or the machinery itself.

- Field Drainage: In field drainage operations, tilt cylinders can be used to adjust the angle of drainage implements, such as scrapers or ditchers. By controlling the tilt of these implements, operators can effectively shape and maintain proper field drainage patterns. Tilt cylinders enable precise and controlled adjustments, ensuring efficient water flow and preventing waterlogging in agricultural fields.

- Crop Residue Management: Tilt cylinders facilitate crop residue management by allowing operators to adjust the angle of implements used for residue incorporation, such as disc harrows or rotary tillers. By optimizing the implement tilt, residue incorporation can be performed effectively, promoting decomposition, weed control, and soil health. Tilt cylinders provide the necessary control to achieve the desired residue management results.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with the hydraulic systems present in agricultural machinery. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for implement adjustment. The hydraulic system allows for responsive and precise movement, enabling operators to adjust the tilt angle according to specific field conditions and requirements.

- Compatibility and Customization: Tilt cylinders are designed to be compatible with different types of agricultural machinery and implement systems. Manufacturers offer tilt cylinders with various specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of agricultural machinery.

Therefore, tilt cylinders can be effectively utilized in agricultural machinery for field work. Whether it involves implement control, contour following, field drainage, crop residue management, or other field-related tasks, tilt cylinders provide the necessary force, control, and adaptability to enhance the performance and productivity of agricultural equipment in the field.

Can tilt cylinders be used in material handling equipment for load manipulation?

Yes, tilt cylinders are commonly used in material handling equipment for load manipulation. These cylinders play a crucial role in enhancing the versatility and efficiency of equipment designed for lifting, moving, and manipulating various types of loads. Here's a detailed explanation:

- Load Tilting: Tilt cylinders enable material handling equipment to tilt loads, allowing for precise positioning and manipulation. By adjusting the tilt angle, operators can optimize load distribution, accommodate uneven surfaces, and ensure secure handling. Tilt cylinders provide the necessary force and control to achieve the desired load tilting, enhancing safety and operational efficiency.

- Load Stabilization: In material handling applications, load stability is essential to prevent shifting, sliding, or toppling during transport or manipulation. Tilt cylinders contribute to load stabilization by allowing operators to adjust the load tilt angle and maintain a stable position. This feature is particularly important when dealing with unbalanced or irregularly shaped loads. By utilizing tilt cylinders, material handling equipment can ensure safe and secure load manipulation.

- Load Dumping: Tilt cylinders also facilitate load dumping in certain material handling equipment. For example, in dump trucks or dumpers, tilt cylinders allow the controlled tilting of the cargo bed to unload the materials. By actuating the cylinders, operators can achieve controlled and efficient dumping of the load, minimizing material waste and optimizing productivity.

- Load Rotation: Some material handling equipment, such as rotating telehandlers or rotating fork attachments, utilize tilt cylinders to enable load rotation. By adjusting the tilt angle, the equipment can rotate the load horizontally, providing flexibility in positioning or transferring materials. Tilt cylinders provide the necessary force and control for smooth load rotation, expanding the equipment's capabilities.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with hydraulic systems present in material handling equipment. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for load manipulation. The hydraulic system allows for precise and responsive movement, enabling operators to adjust the load tilt angle according to specific requirements.

- Customization and Compatibility: Tilt cylinders can be customized to suit different types of material handling equipment and load manipulation applications. Manufacturers offer tilt cylinders with varying specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of material handling machinery.

Therefore, tilt cylinders are widely used in material handling equipment for load manipulation tasks. Whether it involves load tilting, stabilization, dumping, or rotation, tilt cylinders provide the necessary force, control, and flexibility to handle various loads efficiently and safely. Their integration with hydraulic systems and customization options make them indispensable components in material handling applications.

How does a tilt cylinder contribute to precise equipment tilt control?

A tilt cylinder plays a crucial role in achieving precise equipment tilt control. It provides the necessary force and control mechanisms to enable controlled and accurate tilting movements. Here's a detailed explanation of how a tilt cylinder contributes to precise equipment tilt control:

- Force Generation: A tilt cylinder is a hydraulic component that generates the force required to tilt or angle the equipment. It consists of a cylinder housing, piston, and rod assembly. When hydraulic pressure is applied to the cylinder, the piston moves, exerting force on the attached component. The force generated by the tilt cylinder allows for precise and controlled tilting of the equipment.

- Controlled Fluid Flow: Tilt cylinders utilize hydraulic fluid to transmit force and control the tilting movement. The flow of hydraulic fluid is regulated by control valves, which allow operators to control the speed, extent, and direction of the tilt. By adjusting the control valves, operators can achieve precise control over the fluid flow, enabling accurate and controlled tilting of the equipment.

- Range of Motion: Tilt cylinders provide a specific range of motion, allowing for controlled tilting within that range. The range of motion is determined by the design and construction of the cylinder, as well as the attachment points on the equipment. The defined range enables operators to tilt the equipment to the desired angle with precision, ensuring precise control over the tilt position.

- Feedback Mechanisms: Some tilt cylinders incorporate feedback mechanisms such as limit switches or sensors. These mechanisms provide real-time feedback on the position and angle of the tilted component. By monitoring the feedback, operators can precisely adjust the tilt cylinder to achieve the desired tilt angle. This feedback loop enhances the precision of equipment tilt control.

- Operator Input: Tilt cylinders are typically operated by equipment operators who have control over the hydraulic system. Operators can manipulate the control levers or buttons to adjust the hydraulic pressure and flow, thereby controlling the tilt cylinder's movement. The operator's skill and experience in operating the tilt cylinder contribute to achieving precise equipment tilt control.

By combining the force generation capabilities, controlled fluid flow, defined range of motion, feedback mechanisms, and operator input, a tilt cylinder enables precise control over the equipment's tilt. This precision is essential for applications where accurate tilting is required, such as in construction, mining, agriculture, and material handling. The ability to achieve precise equipment tilt control enhances operational efficiency, productivity, and safety in various industries.

editor by Dream 2024-05-14