Product Description

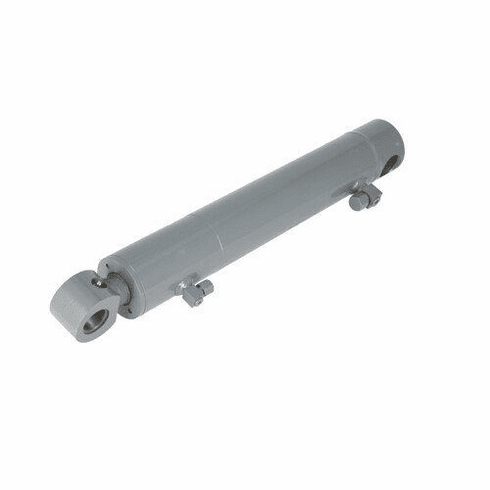

China Professional Manufacture Hydraulic Boom Cylinder for Large Excavator for sale

Hydraulic Boom Cylinder

A hydraulic boom cylinder for a large excavator is a double-acting cylinder used to lift and lower the boom of an excavator. It is 1 of the most enormous cylinders on an excavator and is responsible for raising the heaviest loads. The hydraulic boom cylinder is a vital component of large excavators and is responsible for controlling the movement of the boom arm. The boom arm is an extendable and retractable arm that allows the excavator to reach different heights, angles, and distances.

Specification of Boom Cylinder

Bore diameter: 200mm~420mm

Rod diameter: 140mm~300mm

Stroke≤3500mm

Maximum 4846.6KN

Pressure: 35MPa

Here's how the hydraulic boom cylinder typically works:

-

Hydraulic System: The hydraulic boom cylinder operates within the hydraulic system of the excavator, which consists of a hydraulic pump, control valves, hydraulic hoses or piping, and a hydraulic fluid reservoir. The pump supplies pressurized hydraulic fluid, usually oil, to the system.

-

Cylinder Construction: The hydraulic boom cylinder comprises a cylinder barrel, a piston, and a piston rod. The cylinder barrel is a cylindrical tube with sealed ends. The piston is a cylindrical component that fits snugly inside the cylinder barrel, dividing it into 2 chambers: the rod side (head end) and the cap side (blind end). The piston rod extends from the piston and is connected to the boom arm.

-

Fluid Pressure Application: When pressurized hydraulic fluid is directed to the cylinder's rod side (head end), it pushes against the piston, creating a force that extends the piston rod. The hydraulic pressure is evenly distributed across the piston, generating a balanced force.

-

Boom Arm Movement: As the hydraulic fluid applies pressure to 1 side of the piston, it extends the piston rod, causing the boom arm to extend. This extension enables the excavator to reach farther and higher, allowing for increased CHINAMFG depth and improved material handling capabilities. The hydraulic cylinder provides the necessary force to control the movement and positioning of the boom arm.

-

Retraction: To retract the boom arm, the hydraulic fluid is directed to the cap side (blind end) of the cylinder. The pressure from the fluid pushes against the opposite side of the piston, retracting the piston rod and bringing the boom arm back toward the excavator. This retraction allows for compact storage of the boom arm when not in use.

-

Control Valves: The flow and direction of hydraulic fluid to the boom cylinder are controlled by hydraulic control valves. The equipment operator operates these valves and enables precise control of the boom arm's movement, including extension and retraction. The operator can adjust the boom arm's position and angle to suit the job's specific CHINAMFG or lifting requirements.

-

Sealing: Seals are utilized in the hydraulic boom cylinder to prevent hydraulic fluid leakage and maintain pressure within the cylinder. They are positioned at various points, such as around the piston and piston rod, ensuring a tight seal and preventing fluid from escaping.

Application of Hydraulic Boom Cylinder

The hydraulic boom cylinder has extensive application in various industries requiring large excavators and heavy equipment. Here are some typical applications of hydraulic boom cylinders:

1. Excavation and Earthmoving: Hydraulic boom cylinders are crucial for excavators' CHINAMFG and earthmoving operations. They enable the boom arm to extend and retract, allowing the excavator to reach different depths and distances. This capability is essential for CHINAMFG trenches, excavating foundations, and removing large amounts of soil or debris.

2. Material Handling: Hydraulic boom cylinders are used in excavators for material handling applications. The extendable boom arm, controlled by the hydraulic cylinder, facilitates lifting, moving, and placing heavy objects such as rocks, concrete blocks, pipes, and other construction materials. The precise control offered by hydraulic systems ensures safe and efficient material handling operations.

3. Demolition: Hydraulic boom cylinders are vital in demolition projects. The boom arm, operated by the hydraulic cylinder, enables the excavator to reach and dismantle structures, such as buildings, bridges, and walls. The hydraulic cylinder provides the necessary force and control to manipulate the boom arm for precise and controlled demolition work.

4. Grading and Leveling: Hydraulic boom cylinders are utilized for grading and leveling applications. The extendable boom arm allows the excavator to reach elevated areas and effectively distribute materials, such as soil or gravel, to create even surfaces. The hydraulic cylinder helps adjust the boom arm's angle and position, enabling accurate grading and leveling operations.

5. Mining

Our Company

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has 4 semi-automatic lifting cylinder assembly lines and 1 fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 essays. It has famous CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of critical equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

|

Forklift cylinder assembly shop |

Other types of cylinder assembly shop |

Welding

Painting & coating

|

Painting & coating line |

Fully automatic water-based |

Testing

To further improve product performance, and establish the leadership position of our hydraulic cylinder in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing, using electro-hydraulic control technology, the test conditions preset by computer, which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the valve, are directly processed by the computer and converted to standard units (ml/min; %). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters, such as "oil temperature monitoring, liquid level monitoring, filter device monitoring," etc. Among them, the hydraulic cylinder test stand can test the performance of "load efficiency" and "internal leakage" by readings. At the same time, it is equipped with a grating ruler measuring instrument, which meets the requirements of all test items of hydraulic cylinder products in the national standard.

Our Factory

Packaging & Shipping

| Certification: | GS, RoHS, CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Acting Way: | Double Acting |

| Working Method: | Rotary |

| Adjusted Form: | Regulated Type |

How does a tilt cylinder contribute to stable and safe equipment operation?

A tilt cylinder plays a crucial role in ensuring stable and safe equipment operation. It provides key benefits that enhance stability, control, and overall safety. Here's a detailed explanation:

- Load Distribution: One of the primary ways a tilt cylinder contributes to stability is by facilitating proper load distribution. By adjusting the tilt angle of the equipment's attachment, operators can distribute the weight of the load more evenly. This balanced load distribution helps prevent excessive stress on the equipment, reducing the risk of instability or tipping during operation.

- Center of Gravity Management: Tilt cylinders allow operators to manage the center of gravity of the equipment. By adjusting the tilt angle, they can optimize the positioning of the load and maintain a stable center of gravity. This is particularly important when operating on uneven or inclined terrain. Proper center of gravity management helps prevent equipment imbalance and improves overall stability.

- Operator Control: Tilt cylinders provide operators with precise control over the equipment's tilt angle. This control allows operators to make fine adjustments to the equipment's position, ensuring stability during various tasks, such as material loading, dumping, or maneuvering. The ability to finely control the tilt angle contributes to safe and controlled equipment operation.

- Enhanced Maneuverability: Tilt cylinders improve the maneuverability of the equipment by allowing operators to adjust the tilt angle as needed. This flexibility enables the equipment to navigate through tight spaces, uneven surfaces, or challenging environments more effectively. The enhanced maneuverability reduces the likelihood of accidents or collisions, contributing to safe equipment operation.

- Compatibility with Safety Systems: Tilt cylinders can be integrated with safety systems and features to further enhance equipment stability and operator safety. For example, they can be linked to stability control systems that monitor and adjust the equipment's tilt angle in real-time to maintain stability and prevent tip-overs. Additionally, tilt cylinders may be incorporated into safety interlock systems that prevent certain equipment functions from operating unless the proper tilt angle is maintained, ensuring safe operation.

- Robust Design and Construction: Tilt cylinders are designed and constructed to withstand the demanding conditions of equipment operation. They are built to handle heavy loads, resist external forces, and endure harsh environments. The robust design and construction of tilt cylinders contribute to the overall stability and safety of equipment operation.

Therefore, a tilt cylinder contributes to stable and safe equipment operation through load distribution optimization, center of gravity management, operator control, enhanced maneuverability, compatibility with safety systems, and robust design. By utilizing tilt cylinders, operators can maintain stability, improve control, and mitigate risks, ensuring a safer working environment and reducing the likelihood of accidents or equipment failures during operation.

How does a tilt cylinder contribute to efficient and controlled tilting?

A tilt cylinder plays a crucial role in ensuring efficient and controlled tilting of heavy equipment. It incorporates several features and mechanisms that contribute to this functionality. Here's a detailed explanation:

- Hydraulic Power: Tilt cylinders are typically powered by hydraulic systems, which provide the necessary force for tilting. Hydraulic power allows for smooth and controlled movement, enabling operators to precisely adjust the tilt angle of the equipment.

- Adjustable Force and Speed: Tilt cylinders offer adjustable force and speed, allowing operators to customize the tilting action based on the specific task or load requirements. By adjusting the hydraulic pressure or flow rate, operators can control the force exerted by the cylinder and the speed at which the tilting movement occurs. This flexibility ensures efficient and controlled tilting, regardless of the load or terrain conditions.

- Position Feedback: Many tilt cylinders incorporate position feedback mechanisms, such as position sensors or encoders, which provide real-time information about the cylinder's tilt angle. This feedback enables precise positioning and control of the equipment, allowing operators to achieve the desired tilt angle accurately. It also ensures consistent and repeatable tilting performance, enhancing efficiency and productivity.

- Integrated Valves and Controls: Tilt cylinders often feature integrated valves and controls that enable operators to manipulate the tilting action conveniently. These valves regulate the flow of hydraulic fluid to the cylinder, allowing operators to control the direction and speed of the tilt. Integrated controls, such as joysticks or switches, provide intuitive operation and facilitate precise tilting adjustments.

- Stability and Load Management: Tilt cylinders are designed to maintain stability and manage loads during tilting operations. They are engineered to withstand the forces and stresses associated with heavy loads and dynamic movements. This ensures controlled tilting and minimizes the risk of instability or tipping, contributing to safe and efficient operation.

- Sealing and Lubrication: Tilt cylinders incorporate seals and lubrication systems to minimize friction and ensure smooth operation. Seals prevent leakage and contamination, maintaining the integrity of the hydraulic system. Proper lubrication of the cylinder's moving parts reduces wear and tear, enabling efficient and controlled tilting over an extended period.

By leveraging hydraulic power, offering adjustable force and speed, providing position feedback, integrating valves and controls, ensuring stability and load management, and incorporating sealing and lubrication systems, tilt cylinders contribute to efficient and controlled tilting of heavy equipment. These features empower operators to perform tasks with precision, optimize productivity, and maintain safe working conditions.

What is the importance of regular maintenance for tilt cylinders?

Regular maintenance is crucial for tilt cylinders to ensure their optimal performance and longevity. Proper maintenance helps prevent potential issues, extends the lifespan of the cylinders, and enhances overall equipment reliability. Here are the key reasons highlighting the importance of regular maintenance for tilt cylinders:

- Preventive Maintenance: Regular maintenance allows for the early detection and prevention of potential problems. By inspecting tilt cylinders at regular intervals, any signs of wear, damage, leaks, or misalignment can be identified early on. Timely maintenance interventions, such as lubrication, seal replacements, or component adjustments, can be performed to prevent further damage and costly repairs.

- Optimal Performance: Tilt cylinders that receive regular maintenance are more likely to maintain their optimal performance. Proper lubrication of moving parts, such as pins and bushings, ensures smooth operation and minimizes friction, reducing wear and tear. Regular cleaning and inspection of hydraulic lines and valves help maintain proper fluid flow, ensuring efficient operation of the cylinder. By keeping the tilt cylinder in good condition, equipment operators can rely on consistent and reliable tilting performance.

- Equipment Safety: Well-maintained tilt cylinders contribute to equipment safety. A malfunctioning or poorly maintained tilt cylinder can lead to unexpected failures or accidents, posing risks to operators, bystanders, and the surrounding environment. Regular maintenance helps identify and rectify potential safety issues, ensuring that the tilt cylinder operates safely and reliably during equipment operation.

- Longevity and Cost Savings: Regular maintenance significantly extends the lifespan of tilt cylinders. By addressing minor issues promptly and performing preventive maintenance tasks, the overall wear and tear on the cylinder can be minimized. This prolongs the cylinder's lifespan, reducing the frequency of replacements and associated costs. Additionally, regular maintenance helps avoid costly downtime caused by unexpected cylinder failures, leading to increased productivity and cost savings in the long run.

- Manufacturer Recommendations: Following the manufacturer's recommended maintenance schedule is essential for tilt cylinders. Manufacturers provide specific guidelines on maintenance tasks, intervals, and recommended spare parts. Adhering to these recommendations ensures that the cylinder is properly maintained according to the manufacturer's specifications, preserving warranty coverage and maintaining compliance with industry standards.

In conclusion, regular maintenance for tilt cylinders is vital for their reliable performance, equipment safety, and longevity. By conducting preventive maintenance, ensuring optimal performance, and adhering to manufacturer recommendations, operators can maximize the lifespan of the tilt cylinders, minimize downtime, and enhance the overall efficiency and safety of the equipment.

editor by CX 2023-12-12