Product Description

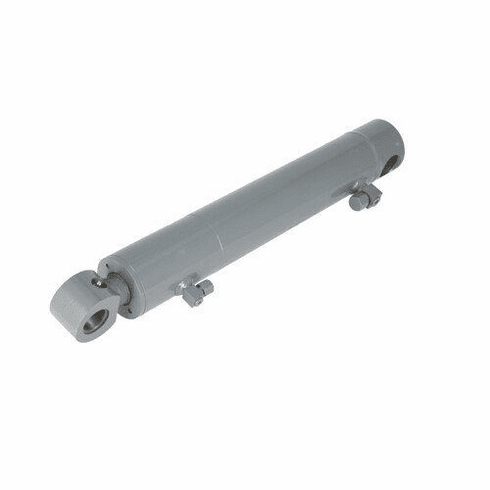

- Product Name: New Hydraulic Bucket Cylinder,Hydraulic Bucket Tilt Cylinder

- Part Number: 6539808,6592584,B18257

- Application Models: Compatible With Bobcat Skid Steer Loaders 843

- Package Include: 1XHydraulic Bucket Cylinder,6539808,6592584,B18257

- Note: 1. This is sold without grease zerks and has a 28" cylinder length.Make sure that this is the correct style cylinder for your machine. Note the difference in length of the cylinder, rod end without grease zerk and the piston rod end recess.

- 2. Please verify rod diameter and port dimensions.

Product Description

Product Name: New Hydraulic Bucket Cylinder,Hydraulic Bucket Tilt Cylinder

Part Number: 6539808,6592584,B18257

Application Models: Compatible With Bobcat Skid Steer Loaders 843

Package Include: 1XHydraulic Bucket Cylinder,6539808,6592584,B18257

Note: 1. This is sold without grease zerks and has a 28" cylinder length.Make sure that this is the correct style cylinder for your machine. Note the difference in length of the cylinder, rod end without grease zerk and the piston rod end recess.

2. Please verify rod diameter and port dimensions

/* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can tilt cylinders be used in manufacturing machinery for material processing?

Yes, tilt cylinders can be used in manufacturing machinery for material processing. These cylinders offer several advantages that enhance the efficiency, versatility, and precision of material processing operations. Here's a detailed explanation:

- Tilt Angle Adjustment: Tilt cylinders allow for precise tilt angle adjustment of equipment attachments, such as cutting tools, milling heads, or processing platforms. This adjustability enables operators to achieve the desired tilt angle for material processing tasks. By controlling the tilt angle, operators can optimize the cutting or processing angle, resulting in improved accuracy, quality, and efficiency.

- Material Positioning: Tilt cylinders assist in proper material positioning during processing. By adjusting the tilt angle of the equipment, operators can align the material in the ideal position for cutting, shaping, or other processing operations. This ensures consistent material engagement with the cutting tools or processing surfaces, minimizing errors and improving overall precision.

- Enhanced Accessibility: Tilt cylinders provide enhanced accessibility to the material being processed. By tilting the equipment, operators can gain better access to different areas of the material, even hard-to-reach or complex surfaces. This accessibility facilitates efficient processing and allows for the execution of intricate operations with greater ease.

- Process Optimization: Tilt cylinders contribute to process optimization by enabling operators to adjust the tilt angle based on specific material characteristics or processing requirements. For instance, certain materials may require a specific tilt angle to achieve optimal chip removal during cutting or to enhance the efficiency of material shaping. The ability to optimize the tilt angle enhances process control and ensures the desired output quality.

- Flexibility in Material Handling: Tilt cylinders provide flexibility in material handling during processing operations. They allow for the tilting of workpieces or platforms, enabling operators to orient the material in the most suitable position for processing. This flexibility accommodates various material shapes, sizes, and orientations, expanding the range of materials that can be effectively processed using the machinery.

- Integration with Automation: Tilt cylinders can be integrated with automation systems in manufacturing machinery. This integration enables automated tilt angle adjustments based on predefined parameters or sensor feedback. By incorporating tilt cylinders into automated material processing systems, manufacturers can achieve consistent and repeatable processing results, reduce manual intervention, and improve overall productivity.

Therefore, tilt cylinders can be effectively utilized in manufacturing machinery for material processing. Whether it involves tilt angle adjustment, material positioning, enhanced accessibility, process optimization, flexibility in material handling, or integration with automation, tilt cylinders contribute to improving the efficiency, precision, and versatility of material processing operations in the manufacturing industry.

How does a tilt cylinder contribute to energy-efficient equipment operation?

A tilt cylinder plays a significant role in promoting energy-efficient equipment operation. By implementing certain design features and functionalities, tilt cylinders help optimize energy usage and improve overall equipment performance. Here's a detailed explanation:

- Accurate Control: Tilt cylinders allow for precise control of the angle and position of attachments or implements, such as blades or buckets. This level of control enables operators to perform tasks with greater accuracy, minimizing the need for rework or additional passes. By achieving the desired angle or position on the first attempt, energy consumption is reduced, leading to more efficient equipment operation.

- Reduced Wasted Effort: Tilt cylinders prevent wasted effort by providing operators with the ability to adjust the tilt angle according to the specific requirements of the task at hand. For example, in grading operations, the ability to fine-tune the blade angle ensures that only the necessary amount of soil is moved, avoiding unnecessary exertion and energy expenditure. By minimizing wasted effort, tilt cylinders contribute to energy conservation and more efficient equipment operation.

- Optimized Material Handling: In equipment like excavators, tilt cylinders allow for precise control of the bucket tilt angle during material handling operations. This optimized control ensures that the right amount of material is loaded or dumped, minimizing spillage and unnecessary movements. By reducing material waste and improving handling efficiency, energy consumption is optimized, resulting in energy-efficient equipment operation.

- Hydraulic System Efficiency: Tilt cylinders are part of the hydraulic system in equipment. A well-designed hydraulic system, including the tilt cylinder, ensures efficient power transmission and minimal energy losses. By utilizing advanced hydraulic technologies, such as efficient pumps, valves, and control systems, equipment manufacturers can optimize the energy efficiency of the overall system, including the tilt cylinder's operation.

- Smart Control Systems: Some modern equipment incorporates smart control systems that integrate with the tilt cylinder. These systems utilize sensors, actuators, and data processing capabilities to optimize equipment operation and energy usage. By analyzing real-time data, such as load conditions, terrain characteristics, and operator inputs, the control system can adjust the tilt cylinder's operation for maximum energy efficiency while maintaining productivity.

- System Integration and Optimization: Tilt cylinders are designed to integrate seamlessly into the overall equipment system. Manufacturers optimize the interaction between the tilt cylinder, hydraulic system, control systems, and other components to achieve energy-efficient equipment operation. Components are selected and engineered to work together harmoniously, minimizing energy losses and maximizing system performance.

By enabling accurate control, reducing wasted effort, optimizing material handling, contributing to efficient hydraulic systems, incorporating smart control systems, and focusing on system integration and optimization, tilt cylinders significantly contribute to energy-efficient equipment operation. These cylinders play a vital role in enhancing productivity while minimizing energy consumption, promoting sustainability, and reducing operational costs.

What is the importance of regular maintenance for tilt cylinders?

Regular maintenance is crucial for tilt cylinders to ensure their optimal performance and longevity. Proper maintenance helps prevent potential issues, extends the lifespan of the cylinders, and enhances overall equipment reliability. Here are the key reasons highlighting the importance of regular maintenance for tilt cylinders:

- Preventive Maintenance: Regular maintenance allows for the early detection and prevention of potential problems. By inspecting tilt cylinders at regular intervals, any signs of wear, damage, leaks, or misalignment can be identified early on. Timely maintenance interventions, such as lubrication, seal replacements, or component adjustments, can be performed to prevent further damage and costly repairs.

- Optimal Performance: Tilt cylinders that receive regular maintenance are more likely to maintain their optimal performance. Proper lubrication of moving parts, such as pins and bushings, ensures smooth operation and minimizes friction, reducing wear and tear. Regular cleaning and inspection of hydraulic lines and valves help maintain proper fluid flow, ensuring efficient operation of the cylinder. By keeping the tilt cylinder in good condition, equipment operators can rely on consistent and reliable tilting performance.

- Equipment Safety: Well-maintained tilt cylinders contribute to equipment safety. A malfunctioning or poorly maintained tilt cylinder can lead to unexpected failures or accidents, posing risks to operators, bystanders, and the surrounding environment. Regular maintenance helps identify and rectify potential safety issues, ensuring that the tilt cylinder operates safely and reliably during equipment operation.

- Longevity and Cost Savings: Regular maintenance significantly extends the lifespan of tilt cylinders. By addressing minor issues promptly and performing preventive maintenance tasks, the overall wear and tear on the cylinder can be minimized. This prolongs the cylinder's lifespan, reducing the frequency of replacements and associated costs. Additionally, regular maintenance helps avoid costly downtime caused by unexpected cylinder failures, leading to increased productivity and cost savings in the long run.

- Manufacturer Recommendations: Following the manufacturer's recommended maintenance schedule is essential for tilt cylinders. Manufacturers provide specific guidelines on maintenance tasks, intervals, and recommended spare parts. Adhering to these recommendations ensures that the cylinder is properly maintained according to the manufacturer's specifications, preserving warranty coverage and maintaining compliance with industry standards.

In conclusion, regular maintenance for tilt cylinders is vital for their reliable performance, equipment safety, and longevity. By conducting preventive maintenance, ensuring optimal performance, and adhering to manufacturer recommendations, operators can maximize the lifespan of the tilt cylinders, minimize downtime, and enhance the overall efficiency and safety of the equipment.

<img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l1.webp" alt="China factory Bllince Solarhome New Hydraulic Bucket Tilt Cylinder 6539808 6592584 B18257 Compatible with Bobcat Skid Steer Loaders 843 vacuum pump oil near me "><img src="https://img.jiansujichilun.com/img/hydrauliccylinders/hydrauliccylinders-l2.webp" alt="China factory Bllince Solarhome New Hydraulic Bucket Tilt Cylinder 6539808 6592584 B18257 Compatible with Bobcat Skid Steer Loaders 843 vacuum pump oil near me ">

editor by Dream 2024-10-12