Product Description

Products Description

|

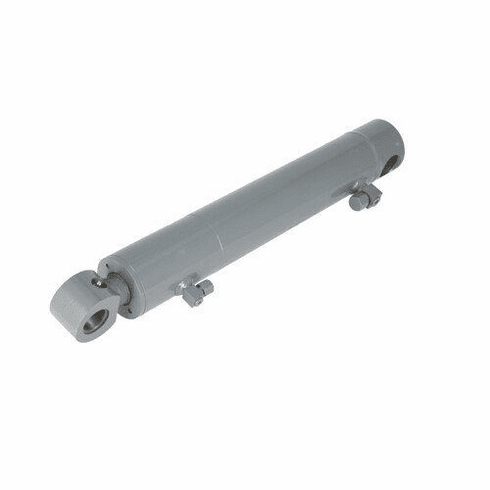

Product Name |

HSG Series Hydraulic Cylinder |

|||

|

Work Press |

7/14/16/21/31.5MPa 37.5/63MPa Can be Customized |

|||

|

Material |

Aluminum,Cast Iron,45mnb Steel,Stainless Steel |

|||

|

Bore Size |

40mm--320mm,Customizable |

|||

|

Shaft Diameter |

20mm--220mm,Customizable |

|||

|

Stroke Length |

30mm--14100mm,Customizable |

|||

|

Rod Surface Hardness |

HRC48-54 |

|||

|

Paint Color |

Black,Yellow,Blue,Brown,Customizable |

|||

|

Mounting |

Earring,Flange,Clevis.Foot,Trunnion,Customizable |

|||

|

Warrenty |

1 Year |

|||

|

MOQ |

1 Piece |

|||

|

Delivery Time |

7-15 Days,Also depands on specific demands |

|||

|

Certification |

ISO9001,CE |

|||

Company Profile

QIANGLIN HYDRAULIC MACHINERY CO., LTD

| QiangLin is a professional hydraulic equipment manufacturer, mainly engaged in hydraulic system design, manufacture, installation, transformation, sales, and technical services. Our manufacturing facilities are certified to the ISO 9001 standard. We are an approved supplier to many equipment manufacturers in China. We are also partners with many customers from America, Canada, Australia, Germany, England, and other European Countries. Product quality, shorter delivery time, and customer satisfaction are our long-term commitments to our CHINAMFG customers. Hope to be your partner. |

FAQ:

Q1: Are you a trading company or a manufacturer?

A: We have our own factory.

Q2: Are you able to make Non-standard or customized products?

A: Yes, we can.

Q3: How long is your delivery time?

A: Normally, the delivery time is 7 days if we have stock, 15-30 working days if we don't. but it

also depends on the product

requirements and quantity.

Q4: Do you provide samples? are the samples free or not?

A: Yes, we can provide samples, but they are not free of charge.

Q5: What are your payment terms?

A: 30% deposit T/T or Irrevocable L/C at sight, If you have any questions, please feel free to

contact us.

Q6: What are your After-sales services?

A: Before shipment, Each individual product will be strictly inspected on our factory QC Process

System. In addition, We have a

Customer Service team to respond to customers' questions within 12 hours. Being helpful in

solving customers' problems is always our goal.

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Normal Temperature |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can tilt cylinders be used in aerial work platforms for platform tilting?

Yes, tilt cylinders can be used in aerial work platforms for platform tilting. These cylinders play a crucial role in enabling safe and controlled tilting of the platform, providing several benefits that enhance the functionality and versatility of aerial work platforms. Here's a detailed explanation:

- Platform Angle Adjustment: Tilt cylinders allow for precise adjustment of the platform angle in aerial work platforms. Operators can control the tilt angle of the platform, allowing for optimal positioning and alignment during work tasks. Whether it involves reaching specific heights, accessing hard-to-reach areas, or accommodating uneven surfaces, the ability to adjust the platform angle enhances the efficiency and effectiveness of work performed on aerial platforms.

- Stability and Safety: Tilt cylinders contribute to the stability and safety of aerial work platforms during platform tilting. They are designed to provide smooth and controlled movement, minimizing platform vibrations or sudden shifts that could compromise operator safety or stability. The cylinders work in conjunction with other safety features, such as stabilizers or outriggers, to ensure that the platform remains stable and secure during tilting operations.

- Load Distribution: Tilt cylinders assist in proper load distribution on the platform. By adjusting the tilt angle, operators can distribute the weight of equipment, tools, or materials more evenly across the platform. This balanced load distribution helps prevent excessive stress on the platform structure and components, enhancing overall stability and safety during work tasks.

- Operator Comfort and Ergonomics: Tilt cylinders contribute to operator comfort and ergonomics in aerial work platforms. By allowing platform tilting, operators can adjust the platform to a more comfortable working position. This reduces operator fatigue and strain, particularly during prolonged work tasks. The ability to customize the platform angle also improves visibility and accessibility, ensuring that operators can work efficiently and safely.

- Enhanced Functionality: Tilt cylinders add versatility and functionality to aerial work platforms. They enable the platform to adapt to various work scenarios and requirements. Whether it involves working on inclines, around obstacles, or at different elevations, the platform tilting capability provided by tilt cylinders allows for greater adaptability and operational flexibility.

- Integration with Control Systems: Tilt cylinders can be integrated with control systems in aerial work platforms. This integration enables precise and automated control of the platform tilting function. Operators can utilize control panels or joysticks to adjust the platform angle, ensuring accurate positioning and enhanced operational efficiency.

Therefore, tilt cylinders can be effectively utilized in aerial work platforms for platform tilting, offering benefits such as platform angle adjustment, stability and safety, load distribution optimization, operator comfort and ergonomics, enhanced functionality, and integration with control systems. These features contribute to the overall performance and usability of aerial work platforms, enabling operators to work efficiently and safely at elevated heights or challenging work environments.

Can tilt cylinders be used in material handling equipment for load manipulation?

Yes, tilt cylinders are commonly used in material handling equipment for load manipulation. These cylinders play a crucial role in enhancing the versatility and efficiency of equipment designed for lifting, moving, and manipulating various types of loads. Here's a detailed explanation:

- Load Tilting: Tilt cylinders enable material handling equipment to tilt loads, allowing for precise positioning and manipulation. By adjusting the tilt angle, operators can optimize load distribution, accommodate uneven surfaces, and ensure secure handling. Tilt cylinders provide the necessary force and control to achieve the desired load tilting, enhancing safety and operational efficiency.

- Load Stabilization: In material handling applications, load stability is essential to prevent shifting, sliding, or toppling during transport or manipulation. Tilt cylinders contribute to load stabilization by allowing operators to adjust the load tilt angle and maintain a stable position. This feature is particularly important when dealing with unbalanced or irregularly shaped loads. By utilizing tilt cylinders, material handling equipment can ensure safe and secure load manipulation.

- Load Dumping: Tilt cylinders also facilitate load dumping in certain material handling equipment. For example, in dump trucks or dumpers, tilt cylinders allow the controlled tilting of the cargo bed to unload the materials. By actuating the cylinders, operators can achieve controlled and efficient dumping of the load, minimizing material waste and optimizing productivity.

- Load Rotation: Some material handling equipment, such as rotating telehandlers or rotating fork attachments, utilize tilt cylinders to enable load rotation. By adjusting the tilt angle, the equipment can rotate the load horizontally, providing flexibility in positioning or transferring materials. Tilt cylinders provide the necessary force and control for smooth load rotation, expanding the equipment's capabilities.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with hydraulic systems present in material handling equipment. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for load manipulation. The hydraulic system allows for precise and responsive movement, enabling operators to adjust the load tilt angle according to specific requirements.

- Customization and Compatibility: Tilt cylinders can be customized to suit different types of material handling equipment and load manipulation applications. Manufacturers offer tilt cylinders with varying specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of material handling machinery.

Therefore, tilt cylinders are widely used in material handling equipment for load manipulation tasks. Whether it involves load tilting, stabilization, dumping, or rotation, tilt cylinders provide the necessary force, control, and flexibility to handle various loads efficiently and safely. Their integration with hydraulic systems and customization options make them indispensable components in material handling applications.

Can tilt cylinders be used for both tilting and leveling applications?

Yes, tilt cylinders can be used for both tilting and leveling applications. They are versatile hydraulic components that are designed to provide controlled tilting movements, as well as facilitate leveling operations. Here's a detailed explanation:

Tilting Applications:

Tilt cylinders are commonly used for tilting applications in various industries. They allow for controlled tilting or angling of components attached to heavy machinery. For example:

- In construction equipment, tilt cylinders enable the adjustment of buckets, blades, or attachments, allowing for precise digging, grading, and leveling of surfaces.

- In mining machinery, tilt cylinders control the angles of buckets or blades, facilitating efficient material handling and excavation.

- In agricultural equipment, tilt cylinders enable the tilting of implements such as plows or buckets, allowing farmers to adjust the working angle for optimal soil tillage or material handling.

- In material handling machinery, tilt cylinders are used to control the tilting of forks, platforms, or attachments, facilitating efficient loading, unloading, and stacking of goods.

Leveling Applications:

In addition to tilting, tilt cylinders can also be used for leveling applications. Leveling involves adjusting the horizontal position or alignment of equipment to ensure even and stable surfaces. Tilt cylinders can assist in leveling operations by:

- Compensating for uneven terrain: Tilt cylinders can be used to adjust the tilt of equipment attachments, compensating for uneven surfaces and maintaining a level position.

- Aligning components: Tilt cylinders can be employed to align or level components such as blades, buckets, or platforms, ensuring consistent and accurate leveling across the working area.

- Providing fine adjustments: The control valves in tilt cylinders allow for precise control of the tilting movement. Operators can make small adjustments to achieve the desired level, ensuring precise leveling.

By utilizing the control capabilities and range of motion of tilt cylinders, operators can effectively perform both tilting and leveling tasks with the same hydraulic component.

In summary, tilt cylinders are versatile and can be used for both tilting and leveling applications. They enable controlled tilting of components in various industries and can also assist in precise leveling operations. The ability to perform both functions makes tilt cylinders valuable hydraulic components in equipment where tilting and leveling are required.

editor by CX 2023-11-20