Product Description

KOMA TSU CHINAMFG SHXIHU (WEST LAKE) DIS.I CHINAMFG PENGPU DOZER VALVE / pump

PARTS RANGE :

radiator , cover , cylinder, lamp , cab , filter, pump , valve , seat , frame , push rod , under carrier , ripper assy , ripper shaft , ripper point , hose ,gasket , repair kit , bearing , bush , pin , transmission , torque converter ,blader , bit end , cutting edge , bolt , nut , engine parts.

FIT MACHINE :

KO MATSU: D31, D50, D60, D65, D85-18, D85-21, D155, D275, D355-3

SHXIHU (WEST LAKE) DIS.I: SD08, SD11, SD13, SD16, SD22, SD23, SD32, SD42 ,

TY130 TY160 TY220 TY230 TY320 SP1-20 (357107) CHINAMFG SD7

357112 CHINAMFG SD7

217638 CHINAMFG SD7

3325963 CHINAMFG SD7

0T31044 CHINAMFG SD7

1B01514 CHINAMFG SD7

1B01462 CHINAMFG SD7

LF777 CHINAMFG SD7

LF670 CHINAMFG SD7

FS1212 CHINAMFG SD7

" KLQ1-42,4300 CHINAMFG SD7 "

WDG1371E 0T22060 CHINAMFG SD7

0T22056 CHINAMFG SD7

1T21069 CHINAMFG SD7

0T22053 CHINAMFG SD7

1G14017 CHINAMFG SD7

1K14009 CHINAMFG SD7

1K14571 CHINAMFG SD7

1F30004 CHINAMFG SD7

0T57116 CHINAMFG SD7

0T57151 CHINAMFG SD7

0T57156 CHINAMFG SD7

0T57163 CHINAMFG SD7

0T5711 CHINAMFG SD7

0T 0571 1 CHINAMFG SD7

0T03033 CHINAMFG SD7

0T03034 CHINAMFG SD7

0T03049 CHINAMFG SD7

0T03066 CHINAMFG SD7

0T03067 CHINAMFG SD7

0T03071 CHINAMFG SD7

0T03083 CHINAMFG SD7

0T03085J CHINAMFG SD7

0T03215 CHINAMFG SD7

0T03322 CHINAMFG SD7

0T04004 CHINAMFG SD7

0T5711 CHINAMFG SD7

0T 0571 1 CHINAMFG SD7

0T5711 CHINAMFG SD7

0T 0571 1 CHINAMFG SD7

0T12167 CHINAMFG SD7

0T12168 CHINAMFG SD7

0T12171 CHINAMFG SD7

0T12177 CHINAMFG SD7

0T12179 CHINAMFG SD7

0T12209 CHINAMFG SD7

0T12210 CHINAMFG SD7

0T12214 CHINAMFG SD7

0T12216 CHINAMFG SD7

0T12217 CHINAMFG SD7

0T12240 CHINAMFG SD7

0T13038 CHINAMFG SD7

0T13042 CHINAMFG SD7

0T13047 CHINAMFG SD7

0T13048 CHINAMFG SD7

0T13056 CHINAMFG SD7

0T13065 CHINAMFG SD7

0T13077 CHINAMFG SD7

0T13079 CHINAMFG SD7

0T13373 CHINAMFG SD7

0T13374 CHINAMFG SD7

0T16309 CHINAMFG SD7

0T16310 CHINAMFG SD7

0T31077 CHINAMFG SD7

0T31078 CHINAMFG SD7

0T31079 CHINAMFG SD7

0T31080 CHINAMFG SD7

0T3552.1-82 CHINAMFG SD7

0T41006 CHINAMFG SD7

0T41008 CHINAMFG SD7

0T44571 CHINAMFG SD7

0T66008 CHINAMFG SD7

0T66571 CHINAMFG SD7

| Warranty: | 12month |

|---|---|

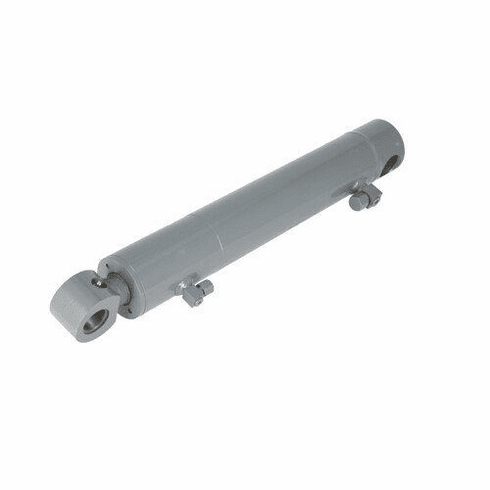

| Type: | Cylinder |

| Application: | Dozer |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Brand: | Shehwa Hbxg |

| Customization: |

Available

|

|

|---|

How does a tilt cylinder contribute to stable and safe equipment operation?

A tilt cylinder plays a crucial role in ensuring stable and safe equipment operation. It provides key benefits that enhance stability, control, and overall safety. Here's a detailed explanation:

- Load Distribution: One of the primary ways a tilt cylinder contributes to stability is by facilitating proper load distribution. By adjusting the tilt angle of the equipment's attachment, operators can distribute the weight of the load more evenly. This balanced load distribution helps prevent excessive stress on the equipment, reducing the risk of instability or tipping during operation.

- Center of Gravity Management: Tilt cylinders allow operators to manage the center of gravity of the equipment. By adjusting the tilt angle, they can optimize the positioning of the load and maintain a stable center of gravity. This is particularly important when operating on uneven or inclined terrain. Proper center of gravity management helps prevent equipment imbalance and improves overall stability.

- Operator Control: Tilt cylinders provide operators with precise control over the equipment's tilt angle. This control allows operators to make fine adjustments to the equipment's position, ensuring stability during various tasks, such as material loading, dumping, or maneuvering. The ability to finely control the tilt angle contributes to safe and controlled equipment operation.

- Enhanced Maneuverability: Tilt cylinders improve the maneuverability of the equipment by allowing operators to adjust the tilt angle as needed. This flexibility enables the equipment to navigate through tight spaces, uneven surfaces, or challenging environments more effectively. The enhanced maneuverability reduces the likelihood of accidents or collisions, contributing to safe equipment operation.

- Compatibility with Safety Systems: Tilt cylinders can be integrated with safety systems and features to further enhance equipment stability and operator safety. For example, they can be linked to stability control systems that monitor and adjust the equipment's tilt angle in real-time to maintain stability and prevent tip-overs. Additionally, tilt cylinders may be incorporated into safety interlock systems that prevent certain equipment functions from operating unless the proper tilt angle is maintained, ensuring safe operation.

- Robust Design and Construction: Tilt cylinders are designed and constructed to withstand the demanding conditions of equipment operation. They are built to handle heavy loads, resist external forces, and endure harsh environments. The robust design and construction of tilt cylinders contribute to the overall stability and safety of equipment operation.

Therefore, a tilt cylinder contributes to stable and safe equipment operation through load distribution optimization, center of gravity management, operator control, enhanced maneuverability, compatibility with safety systems, and robust design. By utilizing tilt cylinders, operators can maintain stability, improve control, and mitigate risks, ensuring a safer working environment and reducing the likelihood of accidents or equipment failures during operation.

Can tilt cylinders be used in material handling equipment for load manipulation?

Yes, tilt cylinders are commonly used in material handling equipment for load manipulation. These cylinders play a crucial role in enhancing the versatility and efficiency of equipment designed for lifting, moving, and manipulating various types of loads. Here's a detailed explanation:

- Load Tilting: Tilt cylinders enable material handling equipment to tilt loads, allowing for precise positioning and manipulation. By adjusting the tilt angle, operators can optimize load distribution, accommodate uneven surfaces, and ensure secure handling. Tilt cylinders provide the necessary force and control to achieve the desired load tilting, enhancing safety and operational efficiency.

- Load Stabilization: In material handling applications, load stability is essential to prevent shifting, sliding, or toppling during transport or manipulation. Tilt cylinders contribute to load stabilization by allowing operators to adjust the load tilt angle and maintain a stable position. This feature is particularly important when dealing with unbalanced or irregularly shaped loads. By utilizing tilt cylinders, material handling equipment can ensure safe and secure load manipulation.

- Load Dumping: Tilt cylinders also facilitate load dumping in certain material handling equipment. For example, in dump trucks or dumpers, tilt cylinders allow the controlled tilting of the cargo bed to unload the materials. By actuating the cylinders, operators can achieve controlled and efficient dumping of the load, minimizing material waste and optimizing productivity.

- Load Rotation: Some material handling equipment, such as rotating telehandlers or rotating fork attachments, utilize tilt cylinders to enable load rotation. By adjusting the tilt angle, the equipment can rotate the load horizontally, providing flexibility in positioning or transferring materials. Tilt cylinders provide the necessary force and control for smooth load rotation, expanding the equipment's capabilities.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with hydraulic systems present in material handling equipment. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for load manipulation. The hydraulic system allows for precise and responsive movement, enabling operators to adjust the load tilt angle according to specific requirements.

- Customization and Compatibility: Tilt cylinders can be customized to suit different types of material handling equipment and load manipulation applications. Manufacturers offer tilt cylinders with varying specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of material handling machinery.

Therefore, tilt cylinders are widely used in material handling equipment for load manipulation tasks. Whether it involves load tilting, stabilization, dumping, or rotation, tilt cylinders provide the necessary force, control, and flexibility to handle various loads efficiently and safely. Their integration with hydraulic systems and customization options make them indispensable components in material handling applications.

What industries commonly use tilt cylinders in their equipment?

Tilt cylinders find applications in various industries where heavy machinery is utilized. These industries rely on tilt cylinders to enable controlled tilting or angling of components. Here are some industries that commonly use tilt cylinders in their equipment:

- Construction: Tilt cylinders are extensively used in the construction industry. They are employed in equipment such as excavators, bulldozers, backhoes, and loaders. Tilt cylinders allow for precise adjustment of buckets, blades, or attachments, enabling efficient digging, grading, and leveling operations.

- Mining: The mining industry utilizes tilt cylinders in equipment like mining shovels, excavators, and haul trucks. Tilt cylinders play a vital role in controlling the angles of buckets or blades, facilitating efficient digging, loading, and material handling in mining operations.

- Agriculture: In the agricultural sector, tilt cylinders are employed in machinery such as tractors, combine harvesters, and agricultural loaders. They enable the tilting of implements, such as plows or buckets, allowing farmers to adjust the working angle for optimal soil tillage, material handling, or crop harvesting.

- Forestry: Tilt cylinders are used in forestry equipment like feller bunchers, skidders, and loaders. They assist in controlling the tilt of cutting heads, grapples, or blades, enabling precise tree felling, log handling, and forestry operations.

- Material Handling: Industries involved in material handling, such as warehouses, distribution centers, and ports, utilize tilt cylinders in equipment like forklifts, reach stackers, and container handlers. Tilt cylinders allow for the controlled tilting of forks, attachments, or platforms, facilitating efficient loading, unloading, and stacking of goods.

- Waste Management: Tilt cylinders are employed in waste management equipment like garbage trucks, waste compactors, and recycling machinery. They enable controlled tilting of containers, compacting units, or sorting mechanisms, enhancing waste collection, compaction, and recycling processes.

These industries represent a few examples of the sectors that commonly utilize tilt cylinders in their equipment. However, tilt cylinders can also be found in other industries where controlled tilting or angling of components is required to optimize operational efficiency and productivity.

In summary, tilt cylinders are widely used in industries such as construction, mining, agriculture, forestry, material handling, and waste management. These industries rely on tilt cylinders to achieve precise control and adjustment of components, enhancing the performance and versatility of their equipment in various applications.

editor by CX 2023-11-18